BMW Case Study

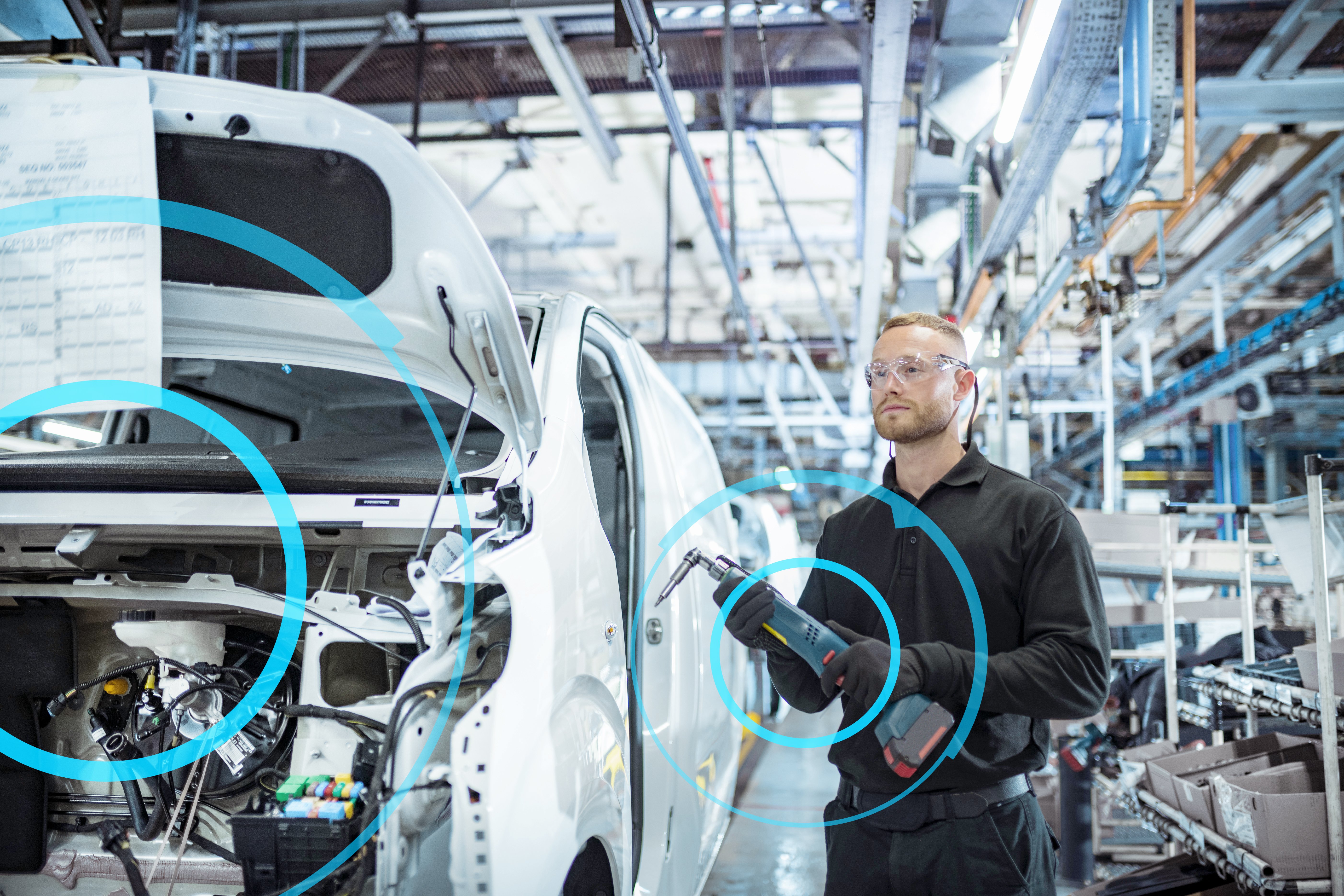

KINEXON X BMW: A Revolutionary Partnership to Automate Manufacturing and Drive Operational Excellence.

Download the Case Study!

"Automotive production at the BMW Group is a lot like top-flight sport in that it's about high-performance processes. The real-time locating platform KINEXON OS forms the backbone for fully digitalizing our production."

‐ Dr. Milan Nedeljković, Board Memeber for Production, BMW AG